What Does Bottleneck Mean in Production?

Bottleneck management in production process.??? ?

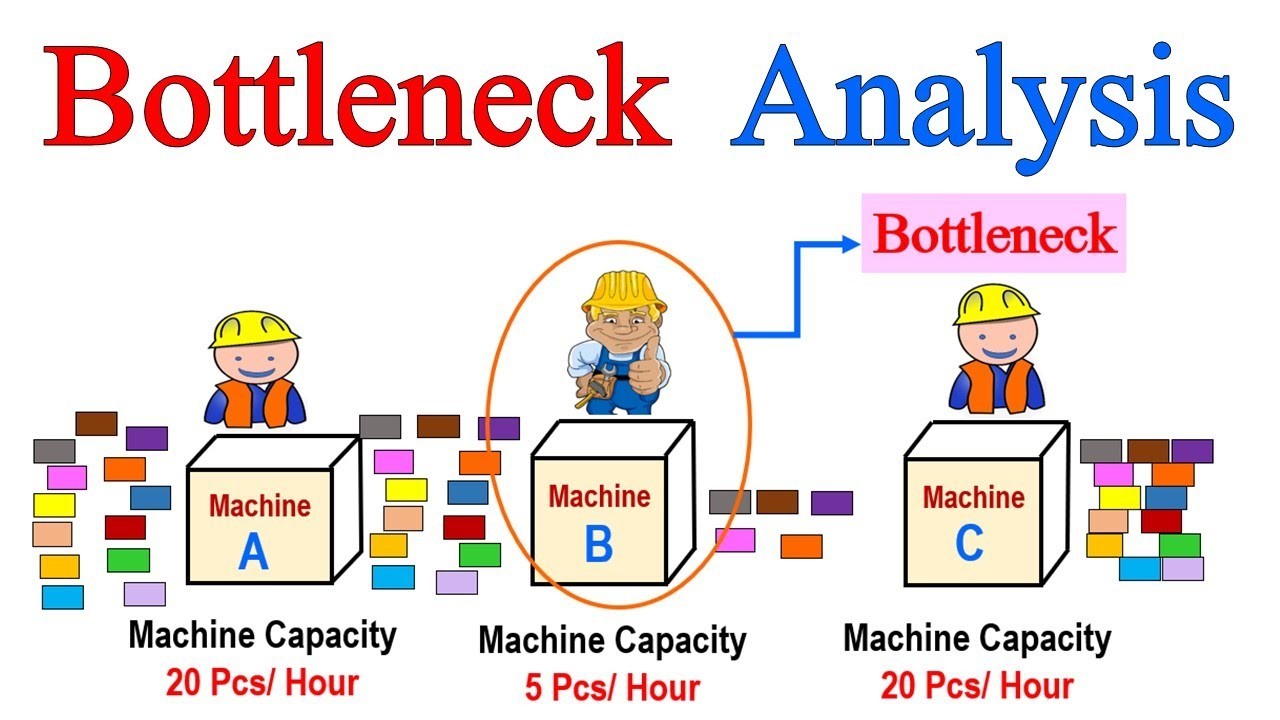

A?basic?bottleneck definition?would be a point along your?manufacturing route?in which production flow becomes constricted, slowing down or even?halting your other production operations.

What Does Bottleneck Mean in Production?

The name, bottleneck,?is?inspired by the function of a bottleneck (on a Coke bottle for example) which?is to stop the content of a bottle quickly spilling out should?it be knocked over. A bottleneck provides a point?in which something passes through slowly.

A?bottleneck?in production?isn’t a congestion point limited to?just?your production line. A bottleneck could occur from your resources, such as:

·???????? A machine?that needs regular?maintenance.

·???????? A worker?who needs training; or

·???????? A computer?with outdated software.

Regardless of where the bottleneck occurs,?it happens due to workloads arriving at a stage of production too early?or the workstation struggling to handle the workload.

So, as you can imagine,?knowing?how to identify?a bottleneck in?production?is extremely important to begin the?debottlenecking?process as soon as possible.

The difference between bottlenecks and?manufacturing constraints?is that a constraint?is a long-term, persistent limiter to your production flow. So, a constraint would be?if your processes are running at their maximum output and can’t be optimized any further.

A?Bottleneck Process Example

It?is easy for a chokepoint to form since the other processes have a smooth production flow, but this particular part of the production line has all?its resources dedicated to the production, meaning that unfinished vehicles are stuck?in waiting before they can be completed.

This part of the factory?is where the?bottleneck?is?occurring,?and you’ll need to find a solution to deal with this.

How to Identify Bottlenecks in Manufacturing?

When looking?into your production processes, you need to monitor any point which has an unpredictable workflow.

And you can do this by following one of the?tactics?below when?investigating?improvements to make to your?bottleneck management:

1. Accumulation? Is there a point along your process steps where a long queue of unfinished products accumulates??If you produce only one type of product,?it can be easy to?identify?where the accumulation?is occurring because you simply walk along the manufacturing route until you find where?the?buildup?is.

2. Throughput Another way of?identifying where bottleneck manufacturing?is appearing?is to?increase the manufacturing throughput of each of your workstations because theoretically, bottlenecks affect your throughput time, so?if a machine?is prone to bottlenecks?the throughput will?increase,?and?it’ll affect the overall production rate.

领英推è

3. Full Capacity Each of your workstations will have a utilization limit.?If there?isn’t a bottleneck along the production line, all workstations will be operating at a similar capacity, let’s say?50% of?its total work capacity.?If a?bottleneck operation?develops, one?workstation?will be operating at a higher capacity, perhaps 80%, while the percentage of utilization drops at other stations, to 45%.

4. Wait times Finally, we have wait times, which?is a simple tactic to?implement for?identifying a?bottleneck?in manufacturing. All?you?have?to?do?is?look at the downtime or waiting times for workstations.

A workstation with a long waiting time means the point prior?is where the?bottleneck?is occurring, as the bottleneck process?is taking too long to finish an operation and?is holding up the rest of the production.

So, once you’ve?identified where the?bottleneck?is?occurring, now you need to figure out how to stop the?bottleneck resource.

How to Start Debottlenecking Your Business??

With the know-how to easily identify a?bottleneck in?manufacturing process, you can now begin the process of?debottlenecking.

And, you’ll be happy to know,?it’s relatively easy to fix a bottleneck.?However, the?issue?is?it?will?eventually?come back,?and the biggest challenge?is quickly catching?it before?it drives up your production costs.

But, once you’ve caught?it, you can begin?debottlenecking?by:

1. Redistributing?resources? It might be as simple?as redesigning the?set-up on your factory floor?or simply?diverting more resources?into the?production bottleneck. Elevating the capacity (more workers or machines) of the bottleneck could allow the workstation to catch up with the backlog during a high period of demand.

2. Decreasing your resources? It might be that a?bottleneck?is occurring because your resources are all dedicated to processes which spend most of their time waiting.

For example, let’s?imagine you make custom electronic skateboards. You have a workstation that?is dedicated to building the board operating at 20%, and a station dedicated to electronics operating at 80%, this would suggest that first station?is mostly?idle and raising production costs.

3. Subcontracting jobs Contract manufacturing?is the process of hiring another third-party manufacturer to help you manage your workflow and easily remove the bottleneck by relieving pressure from a workstation.

4. Automating your business Finally, as mentioned several times prior,?bottleneck management?is a continuous process. Bringing automation?into your business,?in the form of autonomous machines or a piece of?bottleneck software,?is going to help you easily monitor your production flow, identify?bottlenecks, and make the necessary arrangements to fix them.

Automation?is probably the most?important part of tackling bottlenecks.

Conclusion

According to the?bottleneck definition, this?is an unavoidable fact a manufacturer must learn to?overcome.

But, always remember?what?is?the?principle of bottleneck management??To reduce the effect of congestion on your factory floor.

If you can master detecting a bottleneck as?it forms, you can quickly use the above solutions to debottleneck.