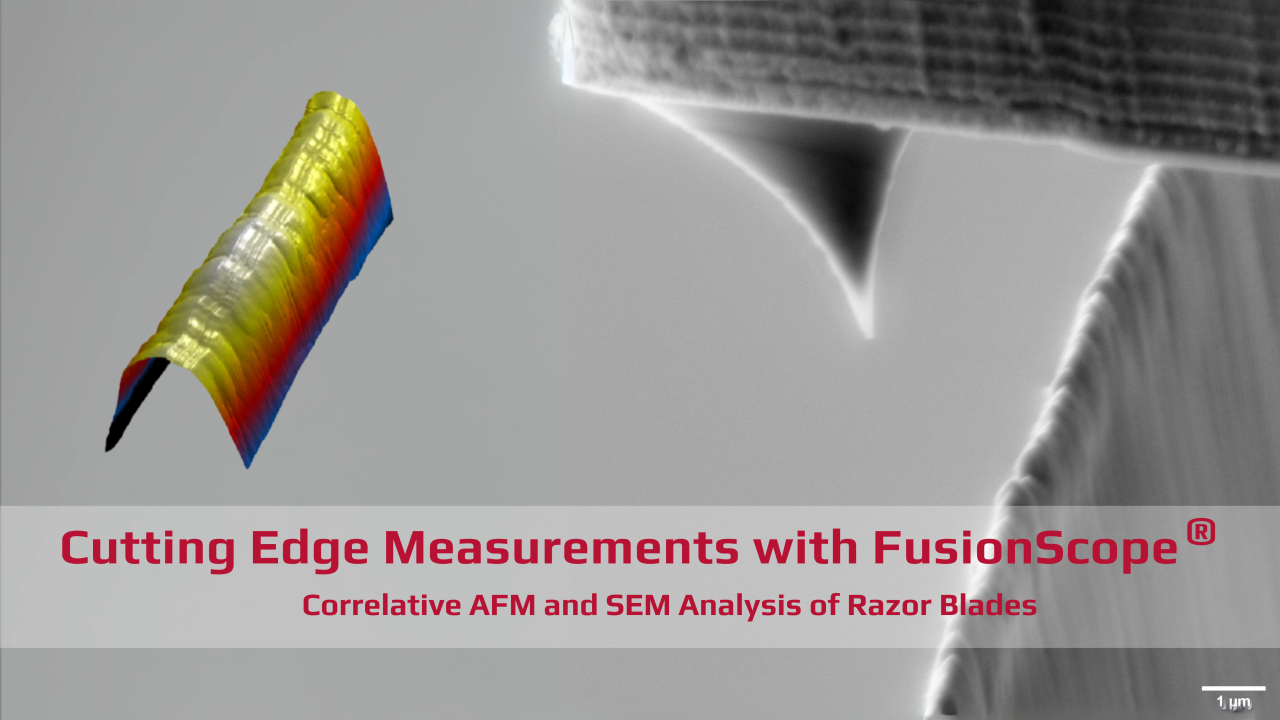

Use complementary information from SEM and AFM to image complex samples like razor blades with nanometre precision.

Correlative microscopy not only enables the integration of complementary information from different microscopy techniques but also facilitates the analysis of challenging samples. In atomic force microscopy, precise measurements of sharply contoured sample geometries are often difficult due to the convolution of the tip's geometry with the surface topography, and accurately positioning the tip over the sample can be problematic. In the following, we demonstrate how correlative microscopy addresses these issues.

The FusionScope? is the first true correlative microscope that seamlessly integrates atomic force microscopy (AFM) with scanning electron microscopy (SEM). Here, SEM assists in optimally positioning the sample and monitoring the AFM measurements in real time.

?

The AFM uses a cantilever beam with a sharp tip to scan a sample, measuring surface topography through cantilever deflection detected by strain sensors, which enables simultaneous correlative measurements with electron microscopy, allowing the results to be superimposed in a shared coordinate system.

In this AppNote, a commercially available razor blade is used as the sample. It was mounted in the sample holder without modification and electrically grounded to prevent charging during SEM imaging. The objective is to image the blade's surface using AFM and specifically determine the blade's radius.

The measurement process involves several stages: coarse positioning, fine positioning, approaching the tip, and finally, measuring the topography. Coarse positioning is carried out using an optical camera, with the cantilever tip being moved to the eucentric point of the SEM. As this point is already known, this step is quite swift. The razor blade is then brought to within approximately one millimetre of the cantilever tip. Fine positioning is achieved with the SEM, allowing real-time observation of both the tip and the top of the razor blade. This enables positioning with an accuracy of well under 1 μm.

At this stage, the cantilever tip can be approached using the FusionScope's software interface. Once the cantilever tip makes contact with the top of the razor blade, the measurement can commence.

领英推荐

Rectangular sections of the topography can be created, and the measurement parameters can be adjusted during the process. The movement of the atomic force microscope’s tip over the sample can be observed live through the electron microscope at any time. A sample section measuring 5 μm x 24 μm can thus be captured with nanometre precision.

Thanks to the fine positioning enabled by the SEM, various areas of the razor blade can be quickly selected and measured. This allows for the straightforward examination of variations across different points of the same sample. Material properties, such as coatings applied to the razor blade, can be compared. Key parameters include the blade’s radius and the surface roughness.

?In conclusion, the FusionScope enables the measurement of even complex samples that are challenging to access, particularly for conventional AFM. By combining the complementary strengths of AFM and SEM, it provides a streamlined workflow for accurately positioning the cantilever on the blade edge and analysing the 3D topography and blade radius.

Go to fusionscope.com to discover more intriguing!

Love the pun!