Unlocking Success Through Continuous Improvement: The Power of the PDCA Cycle

Muhammad Ihtesham Khan

Software Engineering | Artificial Intelligence | Machine learning |Computer Vision | Prompt Engineer | Logical Skill | Python | Communication Skill | Presentation Skill | Research Skill | Mentor

Introduction

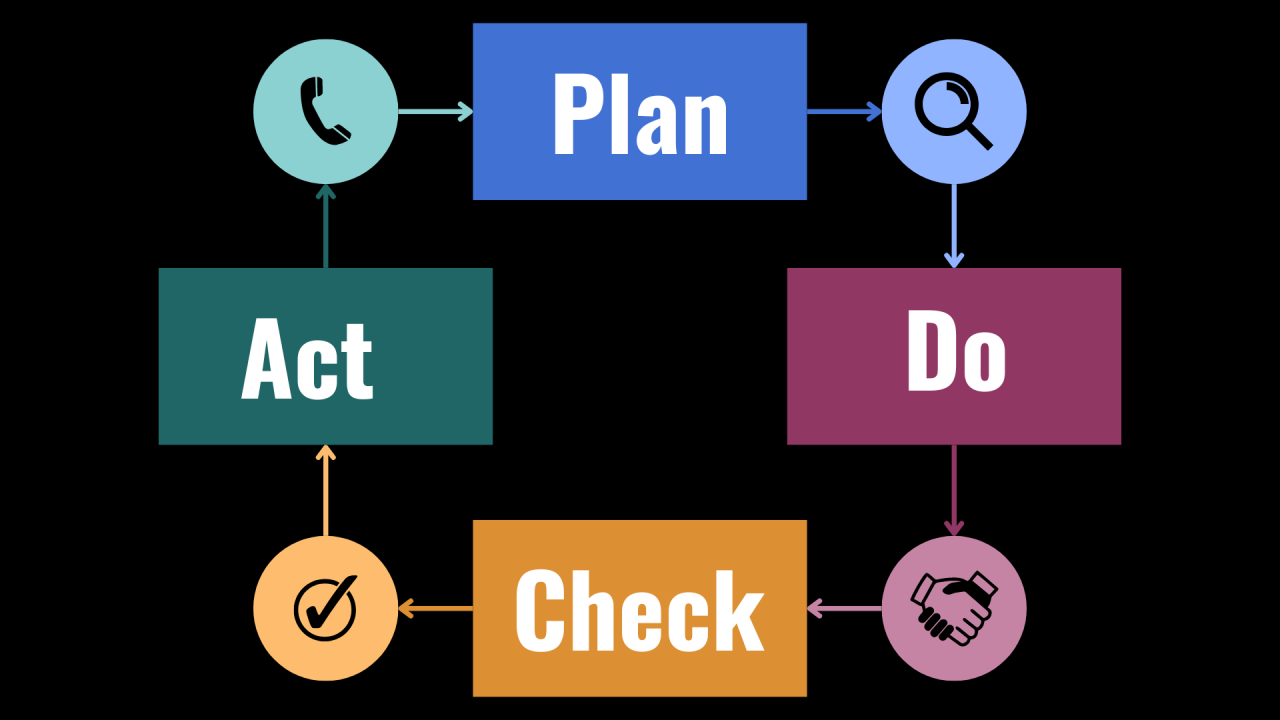

In today’s fast-paced world, standing still is not an option. Whether you’re managing a team, running a business, or developing software, the key to success is continuous improvement. But how do you ensure that improvement is systematic and sustainable? Enter the Plan-Do-Check-Act (PDCA) cycle a powerful framework for driving consistent progress and achieving excellence.

Let’s break down the PDCA cycle and explore how it can be applied to any process, helping you improve, adapt, and succeed.

1?? Plan: Set Your Goals and Define the Process

The first step in the PDCA cycle is planning. This is where you define what you want to achieve and how you’re going to get there. It involves:

Example: Imagine you’re managing a customer service team. Your goal might be to reduce response times. In the planning phase, you’d analyze current response times, identify bottlenecks, and set a target for improvement.

2?? Do: Implement the Plan

With a clear plan in place, it’s time to execute. The Do phase is where you put your plan into action. This involves:

Example: Continuing with the customer service example, you might introduce new software to streamline communication, train your team on its use, and monitor how these changes affect response times.

3?? Check: Review and Analyze the Results

After implementation, the next step is to check the results. This phase involves:

领英推荐

Example: You’d analyze the data collected to see if response times have decreased. Did the new software work as expected? Are there any unexpected challenges?

4?? Act: Make Adjustments and Standardize

The final step in the PDCA cycle is to act based on what you’ve learned. This involves:

Example: If the new software improved response times, you’d standardize its use across the team. If it didn’t, you’d refine your approach and start the cycle again, aiming for better results.

The Continuous Improvement Loop

The beauty of the PDCA cycle is that it’s continuous. After completing one cycle, you start over, building on what you’ve learned and achieved. This iterative process fosters a culture of ongoing improvement, where each cycle brings you closer to your goals.

Conclusion

The PDCA cycle is more than just a framework it’s a mindset. By embracing continuous improvement, you can drive positive change, enhance efficiency, and stay ahead in a competitive world. Whether you’re improving a business process, developing a new product, or refining your own skills, the PDCA cycle provides a structured yet flexible approach to achieving lasting success.

Ready to take your processes to the next level? Start your PDCA cycle today, and watch as continuous improvement transforms your work and your results.

#ContinuousImprovement #PDCA #PlanDoCheckAct #Leadership #BusinessStrategy #ProcessImprovement #Productivity #LeanManagement #Innovation