Unlocking the Power of Total Productive Maintenance (TPM)

Introduction: Elevating Operational Excellence with TPM

Greetings, Lean Enthusiasts!

Implementing Total Productive Maintenance (TPM) is a pivotal strategy as we continually strive for operational excellence. Today, we're diving deep into how to effectively prepare for TPM, ensuring your organization is poised for success. Let's explore key insights from a comprehensive guide that offers a wealth of knowledge on this transformative approach.

Embracing the Fundamentals of TPM

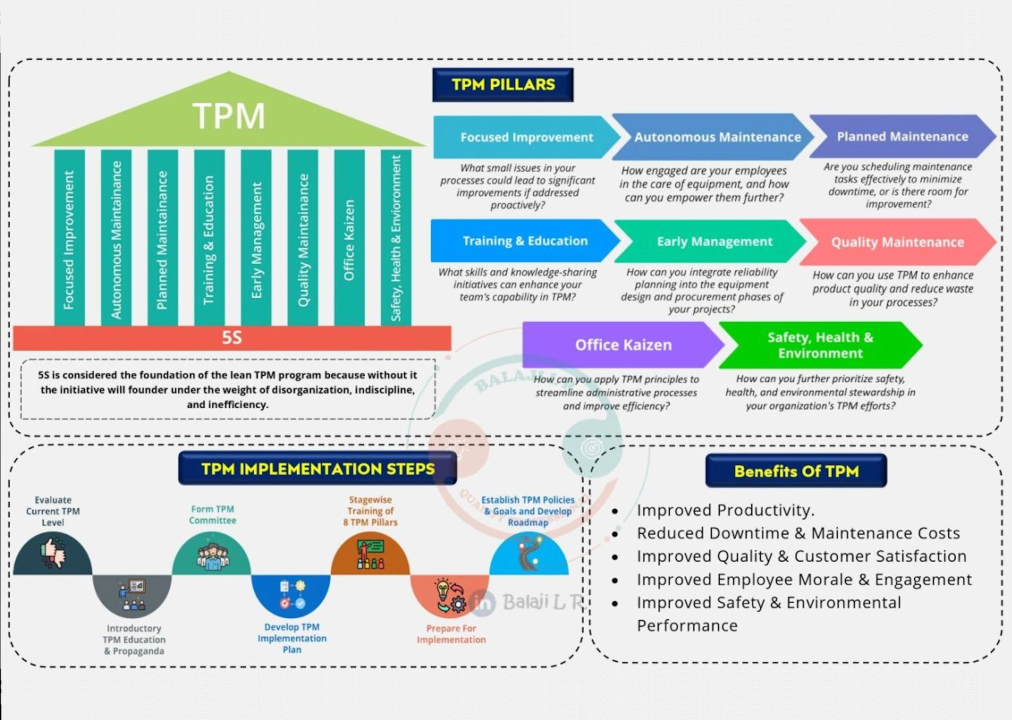

Total Productive Maintenance (TPM) is a holistic approach focused on maximizing equipment efficiency, minimizing downtime, and fostering a proactive maintenance culture. Here are the essential steps to kickstart your TPM journey:

??? 1. Establish a Clear Vision and Objectives: Define your TPM goals. Whether it's reducing downtime, increasing productivity, or enhancing safety, having a clear vision will guide your efforts and align your team.

?? 2. Form a Cross-Functional Team: Bring together a diverse team from various departments. This collaboration ensures that every equipment maintenance and operation aspect is covered, leading to more comprehensive solutions.

?? 3. Conduct a Detailed Assessment: Evaluate your current maintenance practices, equipment performance, and overall operational efficiency. This assessment will help identify areas for improvement and set the stage for impactful changes.

Implementing TPM: Steps to Success

Here's a streamlined approach to implementing TPM in your organization:

?? 4. Identify Critical Equipment: Focus on the equipment that has the most significant impact on your operations. Prioritize maintenance efforts where they will yield the greatest benefits.

?? 5. Develop a Maintenance Schedule: Create a preventive maintenance schedule that includes routine inspections, cleaning, and minor repairs. This proactive approach prevents unexpected breakdowns and extends equipment lifespan.

领英推荐

?? 6. Train and Empower Employees: Invest in training programs to equip your team with the necessary skills and knowledge. Empowering employees to take ownership of maintenance tasks fosters a culture of continuous improvement.

The Role of Visual Management and 5S in TPM

Visual management and 5S are integral to TPM. They provide a structured framework for maintaining organization and efficiency on the shop floor:

??? 7. Implement Visual Controls: Use visual cues such as color-coded tags, charts, and signs to communicate maintenance needs and equipment status. This transparency enhances communication and promotes quick action.

?? 8. Adopt the 5S Methodology: Incorporate the 5S principles (Sort, Set in order, Shine, Standardize, Sustain) to create a clean, organized, and efficient workspace. This foundation supports TPM by ensuring that tools and materials are readily available and equipment is well-maintained.

Monitoring and Continuous Improvement

TPM is an ongoing journey that requires constant monitoring and adaptation:

?? 9. Track Key Performance Indicators (KPIs): Measure the effectiveness of your TPM initiatives using KPIs such as Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), and Mean Time to Repair (MTTR). These metrics provide valuable insights into your progress.

?? 10. Foster a Culture of Continuous Improvement: Encourage feedback from your team and regularly review your TPM processes. Continuous improvement is at the heart of TPM, driving sustained success and operational excellence.

Transforming Maintenance Practices

Implementing TPM transforms maintenance from a reactive to a proactive approach, significantly enhancing operational efficiency and equipment reliability. By following these steps and fostering a culture of continuous improvement, your organization can achieve remarkable results.

Stay tuned for more insights and practical tips on Lean methodologies. Let's continue our journey towards excellence together!

Retired and looking for my next adventure. If I had listened to the words it can't be done I would have never done project improvements, brought teams together, made the job easier, and invented things.

4 个月And always keep in mind that even the little errors can also cause a big picture problem that can be overlooked.