The industrial landscape is undergoing a significant transformation driven by digitalisation. At the forefront of this change lies the concept of digital twins – virtual replicas of physical assets that leverage real-time data and advanced analytics to revolutionise how enterprises manage their infrastructure. This article delves into the intricate relationship between digital twins and enterprise asset management (EAM), exploring the transformative impact on various aspects of asset operations.

Demystifying Digital Twins: A Bridge Between Physical and Virtual

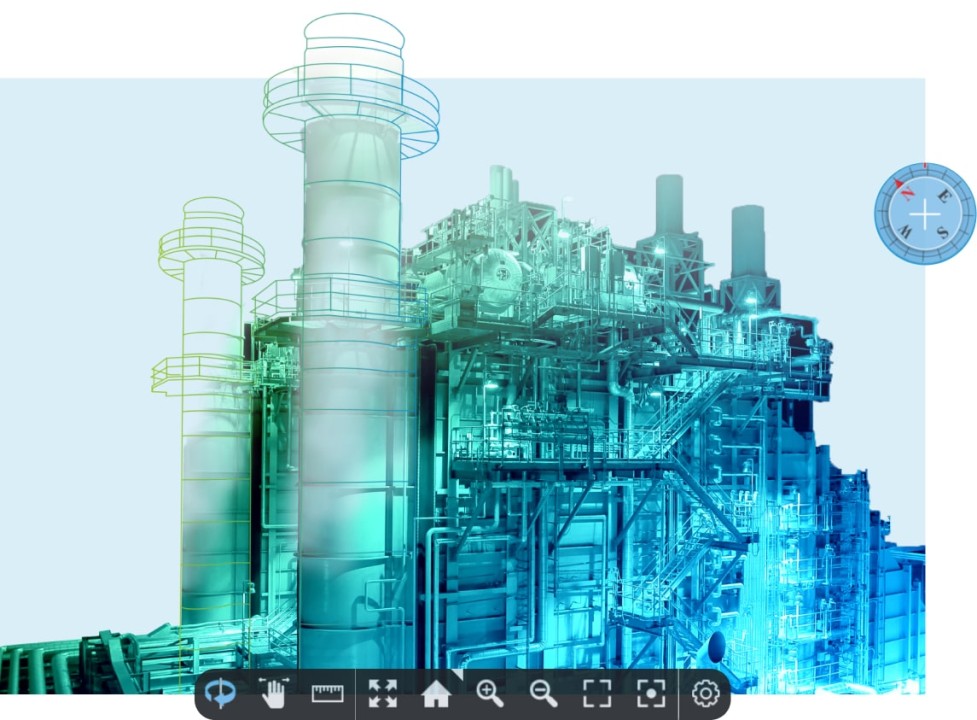

A digital twin is a dynamic software model that mirrors a physical asset in real time. It integrates data from various sources, including sensor readings, historical maintenance records, and design specifications. This data paints a comprehensive picture of the asset's health, performance, and operating conditions. The digital twin acts as a virtual counterpart by continuously analysing this data, mirroring the physical asset's behaviour and predicting future changes.

EAM Redefined: Embracing a Data-Driven Approach

Enterprise asset management traditionally relies on scheduled maintenance routines and reactive repairs. However, integrating digital twins empowers EAM with a proactive and data-driven approach. Let's explore some key benefits of this convergence:

- Predictive Maintenance: Digital twins analyse sensor data to identify trends and predict potential equipment failures before they occur. This enables proactive maintenance, preventing costly downtime and minimising repair expenses. Early detection of issues allows for timely interventions, extending the lifespan of assets and optimising resource allocation.

- Improved Operational Efficiency: Digital twins provide valuable insights into optimising operational processes by continuously monitoring and analysing asset performance. This can involve fine-tuning operating parameters, identifying bottlenecks in production lines, or optimising energy consumption. Real-time data helps identify areas for improvement, leading to a more streamlined and efficient operation.

- Reduced Downtime: Predictive maintenance capabilities enabled by digital twins significantly reduce unplanned downtime. This translates to increased production capacity, improved on-time delivery rates, and enhanced customer satisfaction.

- Risk Mitigation: Digital twins can simulate various operational scenarios, including potential equipment failures and environmental changes. This allows EAM professionals to proactively identify and mitigate risks, ensuring critical assets' safety and reliability.

- Enhanced Decision-Making: By providing a holistic view of asset health, digital twins empower data-driven decision-making. Managers can leverage insights from the digital twin to make informed choices regarding resource allocation, maintenance scheduling, and investment strategies for asset upgrades.

Beyond Maintenance: The Broader Impact of Digital Twins on EAM

The influence of digital twins extends beyond traditional maintenance practices. Here are some additional ways it impacts EAM:

- Integration with Internet of Things (IoT) Devices: Digital twins can integrate with IoT devices to gather real-time data from various sensors embedded within assets, enhancing the accuracy and depth of insights provided.

- Remote Monitoring and Control: Digital twins enable remote monitoring and control, allowing maintenance teams to assess asset performance, diagnose issues, and implement corrective actions from anywhere with an internet connection, improving operational efficiency.

- Lifecycle Management: Digital twins support the entire lifecycle of assets, from design to decommissioning, providing valuable insights at each stage to optimise asset performance over its lifespan.

- Augmented Reality (AR) Integration: Combining digital twins with AR technologies provides technicians with intuitive guidance during maintenance tasks, enhancing productivity and reducing errors.

- Advanced Analytics and Optimization: Machine learning algorithms applied to data collected by digital twins can identify hidden patterns, optimise asset performance, and predict maintenance needs with greater accuracy.

- Regulatory Compliance and Reporting: Digital twins streamline regulatory compliance efforts by providing comprehensive asset performance and maintenance history documentation, simplifying and demonstrating compliance with industry standards.

- Case Studies and Success Stories: Real-world examples demonstrate the measurable improvements in operational efficiency and cost savings achieved by implementing digital twins in asset management practices.

- Continuous Innovation and Adaptation: Emphasize the importance of staying abreast of emerging trends and technologies in digital twins and EAM to drive ongoing improvements in asset management performance.

Building the Foundation: Key Considerations for Implementing Digital Twins

While the benefits of digital twins are undeniable, successful implementation requires careful consideration of several factors:

- Data Integration and Infrastructure

- Data Governance and Security

- Standardisation and Interoperability

- Scalability and Future-Proofing

The Future of EAM: Collaborative Evolution with Digital Twins

The future of EAM lies in a collaborative approach where digital twins seamlessly integrate with existing systems and human expertise. Artificial intelligence (AI) and machine learning (ML) will play a crucial role in further enhancing the capabilities of digital twins. However, human expertise remains irreplaceable, and the future of EAM envisions a collaborative environment where humans play a central role alongside digital twins and AI technologies, leveraging their expertise to optimise asset management strategies and drive continuous improvement.