Orchestrating a Digital Transformation: Making All Your Data Sources Work Together

Probably the single biggest challenge in any enterprise-wide digital transformation is the fact that there are so many essential enterprise systems that need to be integrated. Almost all enterprises have multiple systems that serve the different components of business operations. Systems to enable manufacturing operations are very different from business systems, which are different from customer service systems, which are different from customer resource management, and on and on. Yet all of these enterprise systems - from Manufacturing MRP and ERP systems, to Business Operations Systems, Customer Resource Management Systems, Customer Field Service and Call Center Systems, Internet of Things Data for various devices and systems, as well as multiple IT infrastructure systems - really need to work together for an enterprise-wide digital transformation to work. The volume of systems, as well as the fundamental differences between them, is at the heart of the Digital Transformation challenge.

?And, because different enterprises will have different collections of systems, serious efforts to overcome this end up driving customizations across many of these systems, resulting in long schedules, high costs, and unsatisfactory results, because this is never “standardized”. Further, because of the diversity of these systems, with their inherent divergence in data types, data meaning, and system design, many business transformation efforts are executed “within” each business silo, with only limited intelligence passed back and forth between these silos. The reason for this is that business transformations usually start with one of the existing systems to move the digital transformation forward, but rarely will that system have sufficient built-in capabilities to interwork with the systems in peer organizations. This should not be surprising, as these software applications were never designed to perform this cross-enterprise data transformation, rationalization, and interworking capability, and rarely do they support the kind of modern restful and secure API creation, data transformation, data management, and systems interworking capabilities really needed for success.

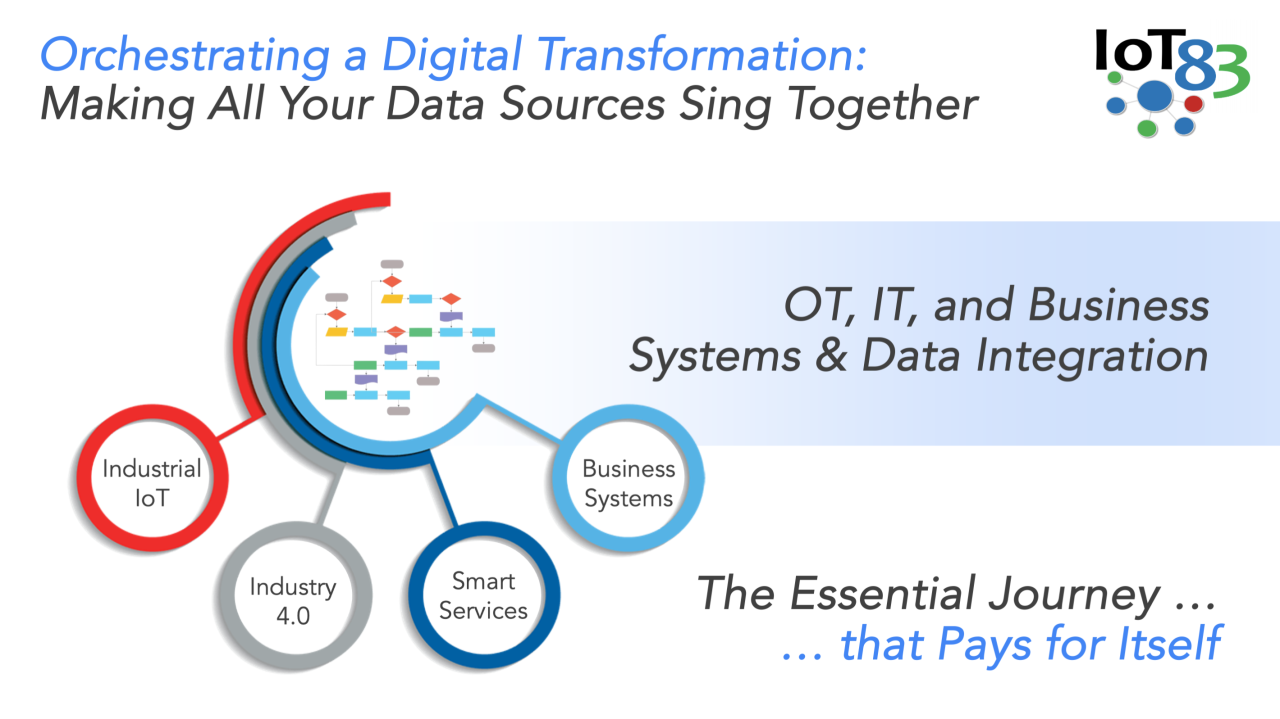

?As a result, to avoid frustratingly slow progress, high costs, even outright program failure, a different approach is really needed. But the good news is this: While these diverse systems rarely include the tools to pull this all together, almost all will have the means to securely connect to the application via a well-defined set of APIs. From our experience at IoT83, leveraging this uniform commonality, along with a modern platform with all of the appropriate tools to build secure connections, transform data, perform enterprise-wide analytics on the data, and to pass value-added “derived data” across to different systems is the best approach. To move this concept forward, consider the diagram below:

Here, a modern and advanced platform such as IoT83’s Flex Platform is used, not only as the essential glue between platforms, but also as a layer to normalize data from each platform to enable that data to be used in analytics to create “derived data” from all the different applications that will have high value cross-silo insight value. This “derived data” can then be used to orchestrate optimizations between the different silos. For example:

? Manufacturing fall-out data can be combined with ERP data to nail-down to the supplier or batch level what components of a system drive these failures.

? Services data can be analyzed to understand customer trouble spots, and the “the cost to cure” (service calls, drop-shipments, truck rolls, etc.) and this can all be fed back to business operations systems or even product management for optimization.

? Product cost Vs profit analysis can now include not only BOM costs, but cost to build, to service, and warranty costs.

? Industrial IoT applications that monitor and manage equipment can feed into field service operations to make them far more efficient, where predictive maintenance allows remediation before failure, and IoT data provides agents with prior knowledge of what needs repair prior to arriving at the job. Further, by using remote device management, some field issues can even be remediated through remote re-configuration of devices or better still through automation.

? These same IoT applications can also be applied to manufacturing in the form of robust device construction validation, adding new levels of assurance that everything that goes out the door is tested at a systems level.

? CRM forecasts can also directly feed into order management systems, and by analyzing any large new accounts won against the likely products they will purchase, accurate predictions can be made as well. Further, shifts in product mix can be anticipated in time to institute cost reduction or quality enhancement programs to further boost profits.

领英推荐

? Finally, by analyzing the data from these multiple silos, the business can truly understand their warranty and SLAs costs and make appropriate quality or cost structure changes.

The underlying technology itself that provides the right “glue” to tie all this together is complicated given the extensive set of features and capabilities, but in modern systems like IoT83’s Flex Platform, implementation of these solutions is now greatly simplified. Again, looking at the diagram above, the Flex Platform at its core provides all of the “Big Data” scalability, reliability, and security “Platform” capabilities. But the Platform also provides all of the essential middleware to tie these systems together:

? Identity Access Management (including Role-Based Access Control and SSO) makes it easy to manage users, but also to securely connect to diverse systems.

? The Gateway services can be used to build secure connections to the diverse set of enterprise systems to bring all of the data from these systems together.

? Data transformation and data management tools simplify normalization of data from diverse systems so that it can be used in enterprise-wide analytics, but also re-formatted as needed to enrich existing systems operation using the analytics results.

? The Analytics Engine, AI/ML tools, notification and scheduling, and multiple other Core Platform Services are all available to build application modules to not only provide new analytics and insights on this enterprise-wide data, but also to use this Platform as a cost-effective way to modernize and extend the capabilities of legacy enterprise systems.

? Finally, the Flex Platform is already an extremely rich Industrial IoT solution in its own right. By implementing all the Flex Platform’s IoT capabilities, any business immediately adds new dimensions to its Smart Products capabilities as well as its ability and velocity in Smart Product execution.

In practice, some of the functions that this intelligent “glue service” provides will be “headless”, with no human interface, in that the results of analytics and new business logic will just be pushed back to the “silo” service for richer insight. But as some of the services this “glue service” provides will be completely new non-siloed information, new use-cases and associated new user interfaces will be necessary. However, this is not a challenge as the Flex Platform provides multiple query and dashboard creation tools.

The silo-busting Digital Transformation described here easily pays for itself very quickly, particularly when using modern a Platform as the foundation. Improvements in the cost of manufacturing and service execution alone usually pay for the entire program, and t Smart Product innovations and competitive edge drive new waves of revenue for years with this investment already covered by the savings realized. And, using industry leading modern solutions like IoT83’s Flex Platform, the cost, risk, and time to value is all very well contained especially when taking a pareto approach to execution.

In closing, for our customers launching these Digital Transformation programs, we advise them to focus on several KPIs that will really move the needle and start the integration and enhancements there, drive for quick wins, integrating only one or two silos at a time, then expand iteratively. And with leading-edge solutions like the Flex Platform this iterative path to success is extremely effective. If this all makes sense to you, please reach out for a discussion on how we can help. We can engage directly with your key stake holders to build a pragmatic plan for fast iterations to drive a powerful Digital Transformation success, and then work side by side with your team for a streamlined execution.

Call us or come take a look at https://IoT83.com. Seeing is believing!