Innovation Through Simulation

Namdeo Rathod

Influencer| Automotive Expert| Product Design & Validation| International Business Development |

Computer-simulated product testing is being used increasingly in modern engineering and manufacturing because it provides a low-risk, time- and cost-efficient means of modeling system performance using a wide array of variables before a physical prototype has been created.

Here we go and outlines some of the uses and advantages of integrating this technology into the product development process. The role of test simulation in product design might not be the general focus of the Structural Engineering. Nowadays, it’s rare to talk about product development without mentioning computer simulation at some point. The aim of this post is to give you a better sense of how test simulation can benefit product development and innovation.

Arnish Engineering Services (AES) is a consulting specializing in structural product solutions to our esteemed customers across the globe. Product innovation for our multi billion dollar companies is at the center while working our customer and using the simulations techniques for the faster, robust and manufacture-able product has been key for AES’s success ever since we have gained the faith of our customers. And with increasing competition and market pressure, product innovation becomes ever more critical to the company’s bottom line.

The ultimate goal of product development is to produce the best design as efficiently as possible. At AES, physics-based computer numerical modeling and simulation already form a key tool in our design process. Research and industry expert says that best-in-class companies were leading the way in utilizing simulation software to arm their employees with the insight needed to develop and optimize today’s products.

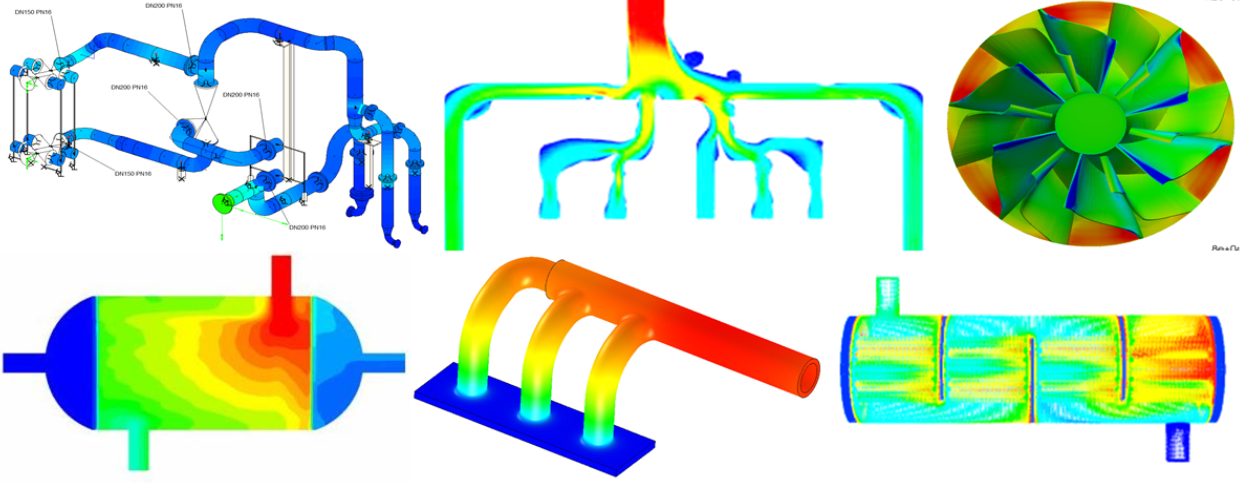

Finite element analysis (FEA) tools have been an essential component of any engineer’s toolbox for years. The ability to create a virtual prototype or realistic representative model of a part or assembly before physical prototyping offers companies a much faster product development path than was previously possible with the physical testing of the product which is very expensive and time consuming method. Most of the time, simulation is used early in the design cycle to investigate a set of predetermined design variable parameters of the designs — in which it has proven to be a more efficient method than running physical tests alone for isolating the best design. At other times, simulation is used alongside physical validation tests to determine whether the design meets specifications and to explore potential failure modes. Now a day many customers implement the simulation techniques in service failure analysis. Voice of customer(VoC) to be incorporated in the early design stages. Along with side of the FEA companies have adopted the CFD - computational fluid dynamics simulation in the product development to find out the impact of air circulation, liquidation, pressure drop and losses, temperature effect etc. at the early stage of the product design. AES expert always advise customer always one step ahead solution and the power / impact of simulations in the product development.

Arnish Engineering always a step ahead product development adopting the simulations techniques to deliver the value to the customer. AES Engineers have not only adopted the simulation in the innovation but adopted the automated simulation process to minimize the human intervention so that the margin of error also can be minimized to enhance the product development process.

When Thomas Edison was asked about finding success amidst failure, he stated, “If I find 10,000 ways something won’t work, I haven’t failed. I am not discouraged, because every wrong attempt discarded is another step forward.”

With computer simulation, one can evaluate many design concepts in a shorter time than one can with physical prototyping. A virtual test workflow drastically reduces the design, prototype and test cycle that are required in a typical product innovation process not only that life and environmental effect on the product over the period also possible. For example, a typical concrete product development cycle involves a long process of concrete pouring, curing and producing physical prototypes. The physical design iteration cycle could take months, whereas a simulation design cycle may take only a couple of weeks.

Another key part of the virtual design process is to try out many variations of design parameters in “what if” scenarios once the computer simulation model is validated and designers have the confidence to use simulation results to guide design decisions. With more and more affordable, high-performance computing power available from cloud or onsite servers, more complex simulations can be performed at a given time. AES Engineers are expert in handling the software and high performance computing machines to simulate the systems and guide the designers. As a result, a faster cycle of virtual trials speeds up the entire product innovation process.

In many cases, hundreds of design concepts are virtually tested before physical prototyping begins. If one has to test the same number design variables with the physical testing and conclude the product design one could have months together time and huge amount of design cost. Therefore “Design-to-Cost” principal has been successful with the help of simulation methodologies. And many product development companies are realizing and adopting the simulations techniques.

Besides improving the speed of development and cutting costs, simulation also helps improve product quality. For example, the global and detailed aspects of product performance can be identified and measured easily using simulation. The insight gained from simulation can be used to troubleshoot product failure and optimize the design.

Simulation enables us to develop new products in a virtual environment built on real-world data with much lower cost or risk. Simulation is already an essential part of the innovation process. Simulation is powering modern manufacturing innovation. We will see this trend accelerate further in the future.

Hence one stop solution for all your product design and simulation issues is Arnish Engineering Services.

Do let us know if you have any queries and questions AES expert will get back to you sooner best of our ability to assist you in your product design process… We are always available for you!

Thank you!!

PEB at PEB

5 年Very neat and nicely explained ??

Free Lance Consultant,

5 年Virtual Prototyping & Virtual Simulations play a Very Important Role in Fastest Conversion of Innovative concepts in to Successful Products. In today’s world of fast changing customer expectations, Successful Launching of Innovative Products is Key to not only for Market & Product Leadership, but also for survival in difficult times.