The Impact of Mesh Quality on the Accuracy and Efficiency of Finite Element Analysis

Finite Element Analysis (FEA) has revolutionized the engineering world, providing powerful tools to simulate and analyze complex physical phenomena. Whether it's designing a new aircraft, optimizing a car's crashworthiness, or ensuring the stability of a skyscraper, FEA plays a crucial role. However, the accuracy and efficiency of these simulations heavily depend on one often overlooked factor: mesh quality.

Understanding Mesh Quality

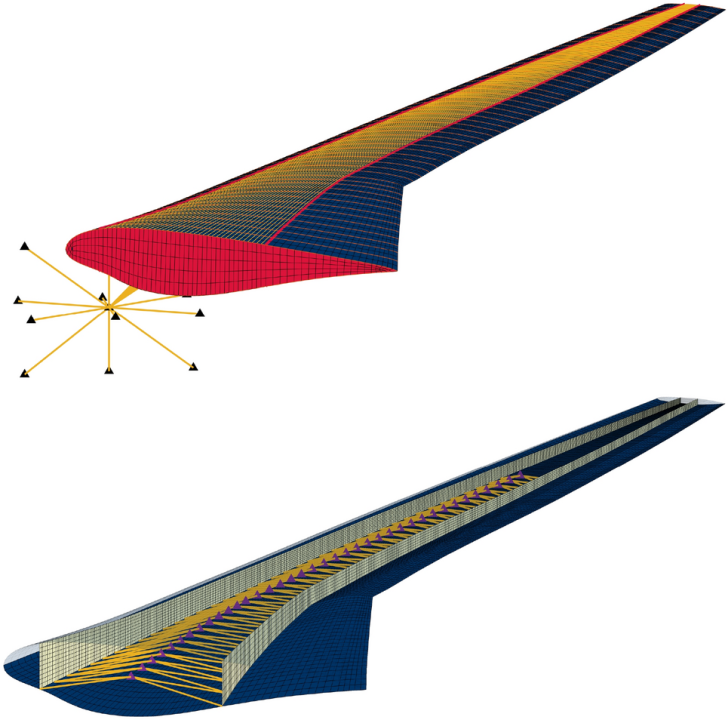

At its core, FEA works by breaking down a complex geometry into smaller, simpler elements—a process known as meshing. The quality of this mesh is paramount. A good quality mesh accurately represents the geometry and boundary conditions of the model while balancing computational efficiency.

Types of Meshes

Meshes can be categorized into structured and unstructured types. Structured meshes have a regular, grid-like pattern, making them easy to generate and computationally efficient. However, they may struggle with complex geometries. Unstructured meshes, on the other hand, can conform to intricate shapes more easily but often require more computational resources.

The Importance of Mesh Quality

Mesh Refinement Techniques

To improve mesh quality, various refinement techniques are employed:

Common Issues with Poor Mesh Quality

Poor mesh quality can manifest in various ways, such as:

领英推荐

Case Studies and Practical Examples

In the aerospace industry, for example, ensuring the mesh quality of a wing structure is critical. A poor mesh can lead to incorrect stress predictions, potentially resulting in catastrophic failure. Similarly, in automotive crash simulations, mesh quality directly impacts the accuracy of deformation and stress distribution predictions, affecting safety assessments.

Software Tools and Techniques

Modern FEA software provides advanced tools for mesh generation and optimization. Programs like ANSYS, Abaqus, and COMSOL offer automated meshing algorithms, adaptive refinement techniques, and quality metrics to assist engineers in creating high-quality meshes.

Future Trends in Meshing Technologies

The future of meshing technology looks promising, with advancements in AI-driven mesh optimization and automated algorithms. These technologies aim to reduce the time and expertise required to generate high-quality meshes, democratizing FEA for broader use.

Conclusion

Mesh quality is a critical factor in the success of Finite Element Analysis. Understanding and optimizing mesh quality not only enhances the accuracy of simulations but also improves computational efficiency, leading to better-engineered products and structures. As FEA technology evolves, the importance of mesh quality will only grow, making it a vital area of focus for engineers and researchers alike.

By understanding and prioritizing mesh quality, we can ensure that FEA remains a powerful and reliable tool in our engineering toolkit, driving innovation and excellence in design and analysis.