Breaking New Ground: How Predictive Maintenance Is Redefining Equipment Management

The demand for the global predictive maintenance market is flooding due to several key factors. This trend is advanced by industrial digitalization and the implementation of principles of Industry 4.0 since companies want to improve procedures and minimize idle time. Further, this growth is propelled by the ever-rising cost of non-planned downtime, which for managers should be about US$ 50 billion every year for the entire manufacturing industry.

The COVID-19 pandemic also sped up efforts to change companies and combine them into a more business-friendly environment with a higher demand for productivity based on intelligence in real-time. By 2032, the market was set at between US$ 78.11 billion as corporate strategies showed growing investment and concentration towards predictive technologies.

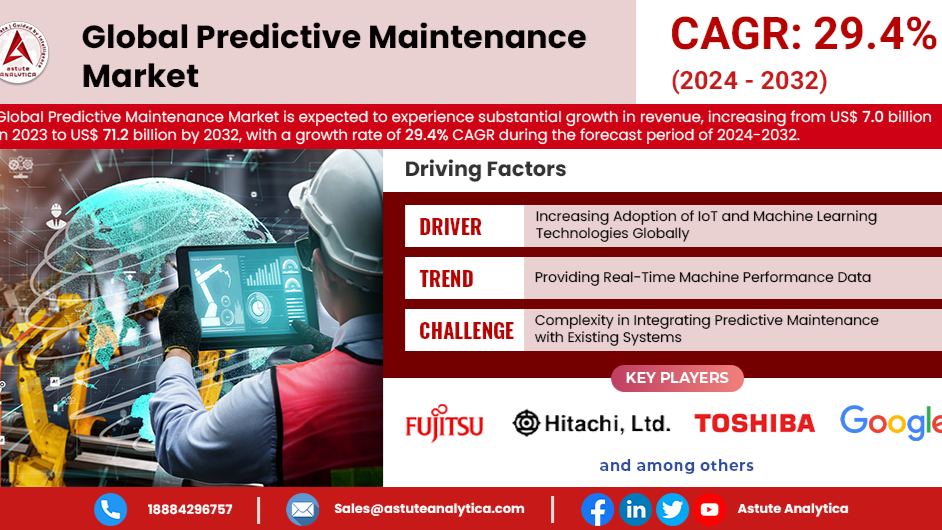

The economic structure of the predictive maintenance ecosystem is still evolving, and a report by Astute Analytica projects that the?global predictive maintenance market is expected to reach a market size of US$ 71.2 billion by 2032, with a compound annual growth rate (CAGR) of nearly 29.4% during the forecast period from 2024 to 2032.

A brief about the market: -

Automated predictive maintenance systems have begun to take the lead thanks to several technological developments. Today, AI and standard machine learning algorithms allow for better-predicting failures and better monitoring of unusual events. Smart sensors and Internet of Things (IoT) devices help in fast data helping to analyze with more than 10 billion IoT-enabled devices currently in usage globally. Primary end users of these solutions cut across industries such as energy and utilities, automotive, manufacturing, healthcare, and transportation. For instance, in the energy market in North America, 3,500 industrial facilities are currently applying predictive maintenance solutions. Likewise, predictive analytics is rapidly adopted in the automotive sector businesses in Europe with approximately 60% forecasting to adopt by 2023.

The predictive maintenance market is changing and developing new applications and technologies too. The trends are moving towards more autonomous forms of failure diagnostics and maintenance approaches where anomaly detection supplements the mainstream predictive maintenance approaches. More and more data sources are used thanks to AI analysis, which augments the reliability of the predictions. Along with this, the market has been noted to include portable and mobile devices, whereby 70% of data tasks will be conducted at the edge by 2025. This will allow on-site real-time data analytics as well as remote data management architectures.

Companies such as SAP SE, Robert Bosch GmbH, IBM Corporation, and Siemens AG have been quite aggressive within the market in terms of pursuing product development activities as well as acquisition activities to stay competitive. The usages of predictive maintenance tend to span from monitoring production line equipment temperature to on-time releasing of additional work orders and balancing the supply chain of labor and parts. The healthcare market is meanwhile gaining traction as a worthy segment with more than 1200 hospitals delivering predictive maintenance for operational efficiency.

Increasing Adoption of IoT and Machine Learning Technologies Globally

The global terrain is noticing a substantial push towards the adoption of IoT and machine learning technologies, specifically in the realm of predictive maintenance. In 2023, over 15 billion devices were connected to IoT demonstrating the development of smart technologies. The global predictive maintenance market alone was valued at US$ 4 billion in the year 2023 and will grow to US$ 12 billion by 2026. The concern for IoT solutions is so high that top companies such as IBM, and Microsoft have set aside US$ 2 billion towards IoT R&D. According to the automotive industry, 35 million vehicles equipped with IoT devices for predictive maintenance exist worldwide. There were even 3,000 patents filled in 2023 for machine learning algorithms utilized in predictive maintenance applications. In addition, over the last year, there have also been over 200 new startups concentrating on IoT-based predictive solutions emerging from these technological waves.

The importance of machine learning in the predictive maintenance market is also turning out to be quite high, as currently over 5,000 algorithms for its turnout have been developed in 2023 alone. Over the past year, cloud computing services that do this saw over 80 million new users. Another sector that has benefited from these technologies is the industrial sector where more than five hundred thousand industrial machines equipped with IoT predictive maintenance sensors were reported. Also, there is an increasing requirement for specialized skills in IoT & machine learning with 150,000 new jobs anticipated in this area by the year 2025. All these figures demonstrate that IoT and machine learning are being adopted by industries at a very fast speed in a bid to enhance functional processes and cut down on the idle time of machines via predictive maintenance.

领英推荐

Providing Real-Time Machine Performance Data

The usage of connected devices in the predictive maintenance market has witnessed an exponential rise, with over 30 million devices deployed for real-time machine performance monitoring in 2023. The manufacturing sector, a major adopter, reported that over 20,000 factories worldwide are now operating connected devices for predictive maintenance. The investment in smart sensors that facilitate real-time data collection is also important, with US$ 1.5 billion spent in this domain last year. As a result, over 100 million data points are collected daily, providing predictive maintenance algorithms. The transportation industry has equipped more than 50,000 fleets with IoT devices to monitor vehicle health in real-time, particularly reducing maintenance costs and enhancing safety. Also, 600 new IoT platforms were introduced in 2023, enabling seamless integration of connected devices across different sectors.

There has been astronomical growth in the usage of connected devices in the predictive maintenance market, with the number of devices that have been deployed for machine performance monitoring in real-time exceeding 30 million by the year 2023. The manufacturing sector, which is a key user of this, information reported that more than 20,000 factories globally are making usage of connected devices for predictive maintenance. In addition, there is also a considerable amount of investment in smart sensors that allow the moving collection of information in only one year, namely this part alone last year cost US$ 1.5 billion. As a consequence, over one hundred million pieces of information are collected daily and absorbed by the predictive maintenance systems.

More than 50 thousand fleets in the transportation business have been provisioned with IoT devices to help handle vehicle health in real-time resulting in substantial savings in maintenance costs as safety was improved. Furthermore, this year, 603 new IoT platforms entered the market due to the seamless integration of connected devices within a business. This only follows the trend where the extension of 5G networks has seen the installation of more than 10,000 5G towers globally to allow these devices to be better connected in the predictive maintenance market.

Recent Launches: -

In 2024, Siemens released a new generative artificial intelligence (AI) functionality into its predictive maintenance solution – Senseye Predictive Maintenance. This advance drives predictive maintenance more conversational and intuitive. Via this new release of Senseye Predictive Maintenance with generative AI functionality, Siemens will make human-machine interactions and predictive maintenance faster and more efficient by improving proven machine learning abilities with generative AI. Senseye Predictive Maintenance utilizes AI and machine learning to automatically generate machine and keep worker behavior models to direct users’ attention and expertise to where it is needed most. Building on this proven foundation, now a generative AI functionality is being presented that will help customers bring existing knowledge from all of their machines and systems out and select the right course of action to help boost the efficiency of maintenance workers.

In 2024, Guidewheel, the leading AI-powered FactoryOps platform, announced the launch of Scout, a new product to help manufacturers predict maintenance requirements and detect early warning signals of issues before they lead to failure or machine downtime. This new AI-driven solution continuously analyzes data about machine performance to detect abnormalities and alert the team to issues they need to know about. Issues that begin as small changes in machine performance often grow into quality problems, preventable downtime, and even catastrophic failure. Too many manufacturers only detect these issues when it is too late, pushing lost production and unforeseen maintenance costs, and shortening the lifespan of critical equipment. Until now, most solutions developed to address these issues have depended on highly invasive vibration sensors, cost tens of thousands of dollars, or have been siloed from the systems plant floor teams use day-to-day, limiting their adoption and effectiveness.

Closing Note: -

The predictive maintenance terrain is growing at an unprecedented pace, propelled by rapid advancements in AI, IoT, and machine learning technologies. As industries globally adopt these innovations, they are realizing substantial advantages in functional efficiency and cost savings. With the market projected to reach significant milestones in the coming years, the focus on real-time data analytics and intelligent diagnostics will only intensify. Companies like Siemens and Guidewheel are at the forefront, driving the boundaries of predictive maintenance with new solutions that promise to improve machine reliability and performance. As people move forward, the integration of these technologies will redefine how businesses approach equipment management, transforming challenges into opportunities for efficiency and growth.