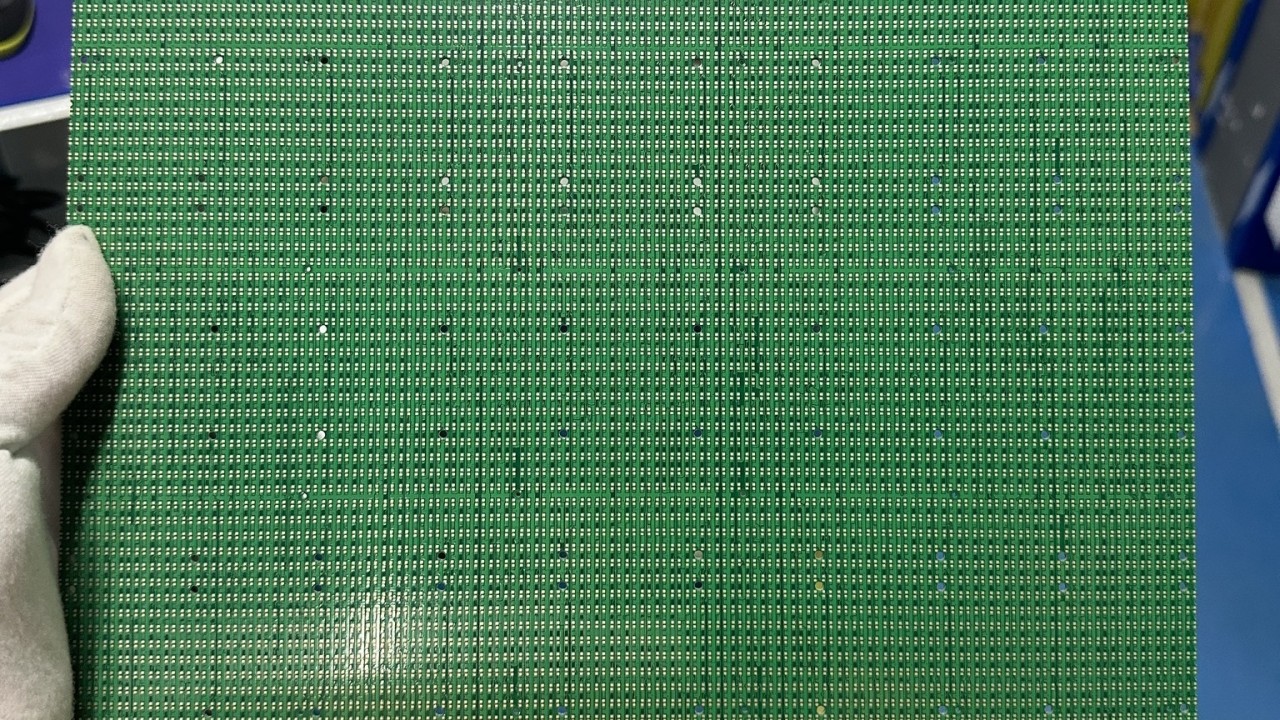

BARE BOARD PRINTED CIRCUIT BOARDS

Bare board printed circuit boards (PCBs) form the foundation of modern electronics, serving as the essential platform for electronic components and circuitry. This comprehensive guide explores the intricacies of bare board PCBs, their manufacturing processes, applications, and critical considerations in their design and production.

Understanding Bare Board PCBs

Definition and Basic Concepts

A bare board PCB, also known as a blank PCB or unpopulated board, is a printed circuit board without any electronic components mounted on it. It consists of conductive pathways etched onto a non-conductive substrate, creating the framework for electronic circuits.

Types of Bare Board PCBs

Single-Sided Boards

Double-Sided Boards

Multilayer Boards

Manufacturing Process

Material Selection

RayMing PCB offers various substrate materials:

Layer Construction

Circuit Formation

Imaging Process

Etching

Surface Finishing

Design Considerations

Layout Guidelines

Signal Integrity

Manufacturing Constraints

RayMing PCB recommends considering:

Quality Assurance

Testing Methods

Electrical Testing

Physical Testing

Industry Standards

Applications

Consumer Electronics

领英推荐

Industrial Equipment

Automotive Electronics

Medical Devices

Advanced Technologies

High-Density Interconnect (HDI)

Rigid-Flex Boards

Embedded Components

Environmental Considerations

RoHS Compliance

Green Manufacturing

RayMing PCB implements:

Cost Factors

Material Costs

Production Volumes

Future Trends

Emerging Technologies

Industry Developments

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a bare board PCB?

A1: The lifespan of a bare board PCB typically ranges from 10 to 20 years when properly manufactured and stored. Factors affecting longevity include environmental conditions, surface finish quality, and storage practices. RayMing PCB's quality control processes ensure optimal board durability.

Q2: How do I choose between different surface finishes for bare board PCBs?

A2: Surface finish selection depends on several factors including:

Q3: What are the minimum trace width and spacing requirements for bare board PCBs?

A3: Standard minimum trace width and spacing is typically 4-6 mils for regular PCBs. However, with advanced technology, traces as thin as 3 mils or less are possible. The specific requirements depend on the manufacturer's capabilities and the board's design requirements.

Q4: How do I ensure proper storage of bare board PCBs?

A4: Proper storage requires:

Q5: What quality certifications should I look for when selecting a bare board PCB manufacturer?

A5: Key certifications include:

Conclusion

Bare board printed circuit boards remain the cornerstone of electronic manufacturing, with continuous advancements in technology driving new possibilities and applications. Understanding their properties, manufacturing processes, and quality requirements is crucial for successful electronic product development. Companies like RayMing PCB continue to push the boundaries of what's possible with bare board PCB technology, ensuring that this fundamental component of electronics manufacturing evolves to meet future challenges and demands.

Founder of Mobotics specializing in Robotics and Electronics innovation

2 个月I love this