Activated Sludge Process Control Calculations-(1)

There are some main things the operator controls when operating an activated sludge unit. The first is the rate at which air is put into the tank. The second is the rate at which sludge is returned to the aeration tank. The third thing to control is the rate at which sludge is wasted from the unit.

Aeration Rate

The air is added to the tank to provide oxygen for the microbes and to mix the microbes and food together. If there is not enough oxygen, the microbes won't work the way you need them to. Also, if the oxygen is too low, additional filamentous microbes will grow and cause problems with the sludge settling. A concentration of 1.0 mg/L is the least you should have but a value of 1.5 mg/L would be a safer minimum to use. If the dissolved oxygen is over 4 mg/L you may just be wasting air and blower costs. If you put in enough air to keep the DO between 1.5 and 4 mg/L, the unit should operate just fine and not waste energy.

Food to Microorganism Ratio

The number of microorganisms which are used to seed the aeration chamber is carefully controlled and is based on the food to microorganism ratio (F/M ratio). The microbes will most efficiently break down the organic matter in water if they are present in the right proportion.

To illustrate this concept, let's consider a similar situation in which you are feeding hamburgers to hungry football players. If you give 100 hamburgers to 10 hungry football players, many of the hamburgers will remain uneaten. In contrast, if you give 10 hamburgers to 100 hungry players, the players will fight over the hamburgers. The hamburgers are likely to get torn to pieces during the fight and will remain uneaten. The perfect hamburger to football player raio is 1-1. If you have 100 hungry football players and 100 hamburgers the players will not fight over the food and will quickly consume all of the hamburgers.

The food to microorganism ratio follows the same concept. If the appropriate food to microorganism ratio is followed, then there will be efficient BOD removal in the aerator. One manufacturer suggests that the best food to microorganism ratio is about 0.6.

Based on the food to microorganism ratio, some sludge is sent to the aeration basin from the clarifier while the rest of the sludge is sent to waste. The sludge recirculation rate is controlled by a pump and valve combination. The valve can be opened or closed as needed in order to secure the optimum F/M ratio.

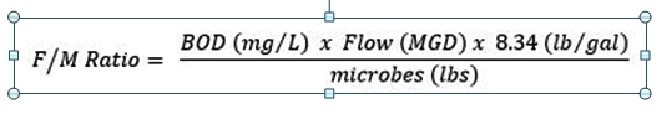

In order to calculate the proper amount of microbes to be added to the aeration basin, you will need to use the following formula: